Understanding the Perks and Innovations in the Aluminum Foundry Market

The Aluminum Foundry sector plays an essential function in modern manufacturing. Its lightweight residential or commercial properties significantly enhance fuel effectiveness, particularly in automobile and aerospace markets. Furthermore, Aluminum's resistance to rust warranties long life in various applications. As the industry develops, developments such as innovative recycling and additive production are improving manufacturing approaches. Exploring these developments reveals not only the advantages yet likewise the difficulties in advance for Aluminum shops in a quickly altering market.

The Lightweight Benefit of Aluminum

Aluminum's light-weight nature uses considerable benefits throughout numerous sectors, particularly in production and transport. Its reduced thickness permits for the production of components that are simpler to install and take care of, causing decreased labor prices and enhanced efficiency. In the vehicle market, lighter vehicles add to boosted gas economic situation and reduced exhausts, lining up with global sustainability objectives. In aerospace, the use of Aluminum minimizes the total weight of airplane, which is crucial for improving efficiency and lowering functional costs.

In addition, Aluminum's lightweight properties promote ingenious designs that were previously unfeasible with much heavier products. This versatility makes it possible for makers to develop complex forms and frameworks while keeping architectural integrity. Generally, the lightweight benefit of Aluminum not only boosts product efficiency yet likewise drives developments in modern technology and design, making it a favored product in various applications.

Deterioration Resistance and Toughness

The Aluminum Foundry industry is renowned for creating products with premium corrosion resistance, making them suitable for various applications. This building, combined with improved architectural honesty, contributes to the resilient performance advantages that Aluminum parts offer. Consequently, sectors increasingly rely upon Aluminum to satisfy requiring ecological conditions without endangering quality.

Superior Deterioration Resistance

While numerous steels face considerable obstacles from ecological aspects, Aluminum attracts attention for its exceptional rust resistance, making it a favored selection in many applications. This building is largely as a result of a natural oxide layer that bases on the Aluminum surface, providing a barrier against wetness and corrosive agents. Unlike other metals that might corrosion or break down gradually, Aluminum keeps its honesty also in severe environments, such as seaside areas or industrial settings. Additionally, its lightweight nature integrated with rust resistance makes it optimal for applications in aerospace, automobile, and marine industries. Overall, Aluminum's phenomenal durability not only boosts item durability but likewise reduces upkeep expenses, presenting a compelling benefit for customers and makers alike.

Boosted Architectural Honesty

Designers and developers significantly identify the relevance of boosted structural stability in modern-day applications, where both deterioration resistance and longevity are critical. Aluminum alloys, understood for their lightweight buildings, also show phenomenal resistance to corrosion, making them suitable for severe atmospheres. The innovative methods employed in the Aluminum Foundry industry add considerably to generating components with improved durability. Advanced casting procedures and alloy make-ups are tailored to meet details performance demands, making sure that structures can hold up against extreme conditions without jeopardizing integrity. Additionally, surface area treatments and layers improve the life-span of Aluminum items, further mitigating degeneration over time. This focus on improved architectural honesty not just extends the functionality of products yet also decreases upkeep costs, solidifying Aluminum's position as a product of choice in various industries.

Lasting Efficiency Advantages

Lasting performance in Aluminum components is mainly credited to their exceptional corrosion resistance and resilience. Unlike many metals, Aluminum normally creates a protective oxide layer, which avoids rust and degeneration in numerous environments, including marine and commercial setups. This intrinsic property considerably extends the lifespan of Aluminum items, lessening upkeep and replacement costs. Additionally, the light-weight nature of Aluminum enhances its applicability across industries without endangering strength. The product's resistance to damage likewise adds to its reliability in requiring applications, making it an excellent option for auto, aerospace, and building and construction markets. As markets increasingly prioritize sustainability and long life, Aluminum's performance advantages line up with contemporary engineering demands, solidifying its duty in innovative production procedures.

Ecological Impact and Sustainability

As the Aluminum Foundry industry progresses, it progressively focuses on environmental effect and sustainability, identifying the demand for responsible methods when faced with climate adjustment. Efforts to reduce waste and power consumption go to the center, with numerous factories adopting recycling campaigns to reclaim Aluminum scrap. This not only reduces raw material usage but additionally significantly cuts down power expense, as recycled Aluminum calls for only a portion of the power compared to main manufacturing.

As the Aluminum Foundry industry progresses, it progressively focuses on environmental effect and sustainability, identifying the demand for responsible methods when faced with climate adjustment. Efforts to reduce waste and power consumption go to the center, with numerous factories adopting recycling campaigns to reclaim Aluminum scrap. This not only reduces raw material usage but additionally significantly cuts down power expense, as recycled Aluminum calls for only a portion of the power compared to main manufacturing.Advancements in emissions manage innovations are being carried out to decrease air pollutants, aligning procedures with more stringent environmental policies. Factories are also checking out different power resources, such as solar and wind, to power their facilities sustainably. By promoting cooperation with stakeholders, the sector intends to establish ingenious solutions that enhance eco-friendly stewardship. Jointly, these initiatives highlight a commitment to decreasing the Aluminum Foundry's carbon footprint while advertising a round economic situation within the production industry.

Advanced Manufacturing Techniques

Changing manufacturing procedures, the Aluminum Foundry market is progressively incorporating advanced production methods to enhance performance and accuracy. Techniques such as computer system numerical control (CNC) machining and additive production have emerged as essential parts in enhancing manufacturing operations. CNC machining enables for high-precision part construction, greatly decreasing product waste and manufacturing time. Additive manufacturing opens new opportunities for complex geometries and lightweight designs that were formerly difficult to accomplish.

Changing manufacturing procedures, the Aluminum Foundry market is progressively incorporating advanced production methods to enhance performance and accuracy. Techniques such as computer system numerical control (CNC) machining and additive production have emerged as essential parts in enhancing manufacturing operations. CNC machining enables for high-precision part construction, greatly decreasing product waste and manufacturing time. Additive manufacturing opens new opportunities for complex geometries and lightweight designs that were formerly difficult to accomplish.Additionally, the implementation of automation and robotics in Aluminum foundries enhances operations, reduces human mistake, and improves worker safety and security. These innovations promote a more receptive production environment, allowing suppliers to adapt swiftly to market needs. The integration of advanced simulation software additionally boosts the design and testing phases, leading to superior item top quality. Collectively, these strategies not only boost functional efficiency anchor but likewise foster technology, positioning the Aluminum Foundry industry at the leading edge of modern-day production.

Advancements in Recycling Procedures

The Aluminum Foundry market is not only advancing in manufacturing techniques yet is additionally making substantial strides in reusing procedures. Technologies are arising to improve the performance of reusing techniques, decreasing energy consumption and improving sustainability. Advanced arranging modern technologies, such as computerized optical sorting, make it possible for the identification and separation of Aluminum from other materials with high accuracy. This leads to a better of recycled Aluminum, which is crucial for maintaining the honesty of the final products.

Closed-loop recycling systems are being implemented, permitting makers to recycle Aluminum scrap within their own production procedures. This minimizes waste and advertises a round economic situation. Furthermore, research into new recycling techniques, such as hydrometallurgical processes, uses the potential for recuperating Aluminum from complex waste streams. These innovations not only add to minimizing the carbon impact of the Aluminum Foundry sector but additionally bolster its economic practicality in a significantly ecologically conscious market.

Applications Throughout Various Industries

Many industries are progressively identifying the flexibility and advantages of Aluminum Foundry products, causing widespread applications throughout industries such as vehicle, building and construction, aerospace, and consumer products. In the auto market, Aluminum spreadings add to lightweight car layouts, enhancing fuel effectiveness and efficiency. Aerospace suppliers utilize Aluminum elements for their strength-to-weight proportion, important for aircraft structures and elements.

In construction, Aluminum is preferred for its durability and resistance to corrosion, making it ideal for home window frames, roof, and structural supports. Customer goods also gain from Aluminum Foundry products, as seen in kitchenware, electronics, and packaging, where lightweight and recyclable materials are essential.

The adaptability of Aluminum Foundry methods enables for precise specifications and intricate designs, dealing with the diverse needs of these sectors. As an outcome, Aluminum Foundry items are coming to be integral to modern-day production procedures throughout different markets.

Future Trends in Aluminum Foundries

As industries continue to evolve, Aluminum shops are positioned to accept a number of crucial patterns that promise to boost effectiveness and sustainability. One popular pattern is the boosting adoption of digital technologies, consisting of automation and expert system, which streamline procedures and enhance quality control. On top of that, the push in the direction of lasting practices is leading shops to spend in recycling modern technologies, substantially minimizing waste and power consumption.

One more arising trend is using advanced alloys and products, satisfying the growing demand for lightweight and sturdy components across different fields (Aluminum Foundry). Additionally, the combination of additive production strategies is anticipated to reinvent part style, using modification and decreasing preparations

One more arising trend is using advanced alloys and products, satisfying the growing demand for lightweight and sturdy components across different fields (Aluminum Foundry). Additionally, the combination of additive production strategies is anticipated to reinvent part style, using modification and decreasing preparationsCollaboration with research organizations is likewise anticipated to drive innovation, as factories look for to develop new processes and products. Aluminum Foundry. Jointly, these fads show a transformative future for the Aluminum Foundry sector, lining up with wider objectives of sustainability and performance

Regularly Asked Inquiries

What Are the Normal Prices Connected With Aluminum Foundry Manufacturing?

The typical expenses related to Aluminum Foundry manufacturing consist of raw products, labor, energy, devices upkeep, and overhead expenditures. These variables jointly influence the overall financial investment required for reliable Aluminum spreading procedures.

Just How Does Aluminum Contrast to Various Other Steels in Stamina?

Aluminum, while lighter than lots of steels, shows impressive strength-to-weight proportions. Contrasted to steel, Aluminum is much less solid but provides outstanding deterioration resistance, making it a beneficial choice in applications where weight and sturdiness are necessary.

What Security Measures Are in Area in Aluminum Foundries?

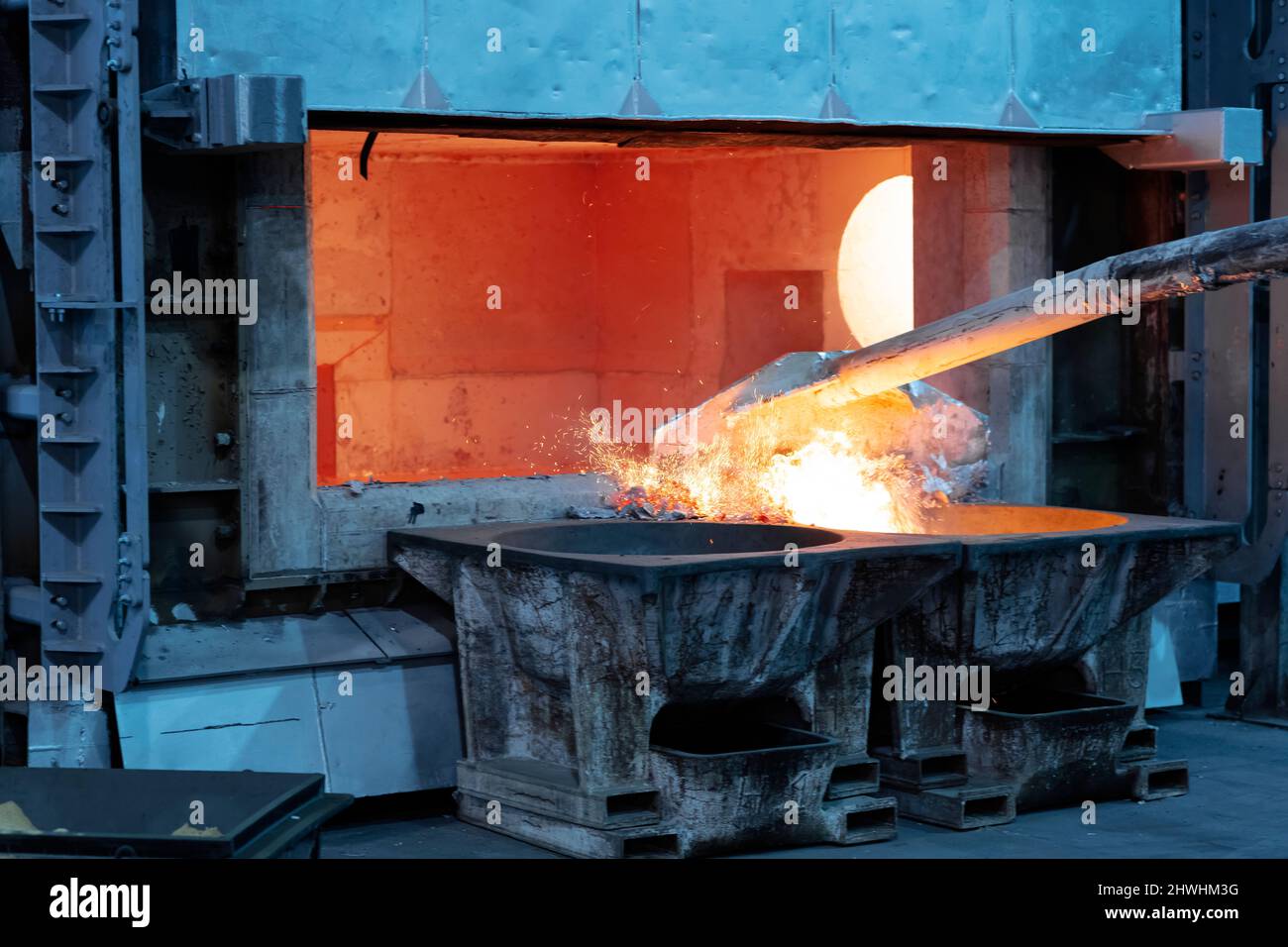

Precaution in Aluminum factories commonly consist of necessary personal safety equipment, ventilation systems to regulate fumes, routine equipment upkeep, training programs for workers, and adherence to stringent safety policies to reduce threats related to molten metal handling.

How Is Quality Assurance Managed in Aluminum Casting Processes?

Quality control in Aluminum casting procedures includes rigorous inspections at various phases, consisting of raw product examination, process monitoring, and last product testing. Strategies such as analytical process control and non-destructive screening guarantee adherence to market criteria.

What Qualifications Are Essential for Aluminum Foundry Providers?

The relevance of certifications for Aluminum Foundry vendors includes ISO 9001 for top quality administration, ISO 14001 for ecological management, and industry-specific standards like ASTM and SAE, making certain compliance, safety and security, and reliability in producing procedures.

The Aluminum check these guys out Foundry industry plays a crucial duty in modern production. The Aluminum Foundry industry is renowned for creating materials with premium corrosion resistance, making them perfect for numerous applications. Revolutionizing production processes, the Aluminum Foundry sector why not look here is significantly incorporating advanced manufacturing methods to enhance effectiveness and precision. The Aluminum Foundry industry is not only advancing in making techniques but is likewise making considerable strides in recycling processes. As markets continue to develop, Aluminum factories are positioned to embrace a number of essential patterns that guarantee to improve efficiency and sustainability.